Biomass Pellet Plant Manufacturers in India – Overview

Major Components of a Biomass Pellet Plant

Conclusion

The biomass industry in India is rapidly transforming the renewable energy landscape by converting agricultural waste and organic residues into efficient, eco-friendly fuel pellets. With India producing hundreds of millions of tons of crop residues annually, the potential for biomass pellet production is enormous. Biomass pellets offer a reliable alternative to conventional fossil fuels, addressing the issues of crop burning and air pollution in states like Punjab and Haryana.

At Pellet Burner India, we take pride in being among the leading biomass pellet plant manufacturers in India, committed to providing world-class pellet plant equipment, manufacturing solutions, and technical support that align with your energy and sustainability objectives.

A biomass pellet plant is an industrial facility where agricultural residues, forestry waste, or other organic biomass are processed and compressed into uniform pellets. These pellets serve as a high-energy, easy-to-store, low-emission fuel source used in:

This process not only creates a valuable renewable fuel but also significantly reduces waste and environmental pollution.

At Pellet Burner India, our end-to-end solutions are designed with quality, performance, and sustainability in mind:

✅ Complete Turnkey Plant Solutions – From initial consultation to installation and after-sales support.

✅ High-Efficiency Pellet Machines – Built for durability, high throughput, and energy-efficient operation.

✅ Customised Plant Design – Engineered based on raw material type, capacity needs, and budget.

✅ Industry Expertise – Trusted by 2000+ clients across sectors for reliable and robust biofuel plant solutions.

Whether you are setting up a small-scale pellet plant or installing a large production facility, we help you maximize output while minimizing operational costs.

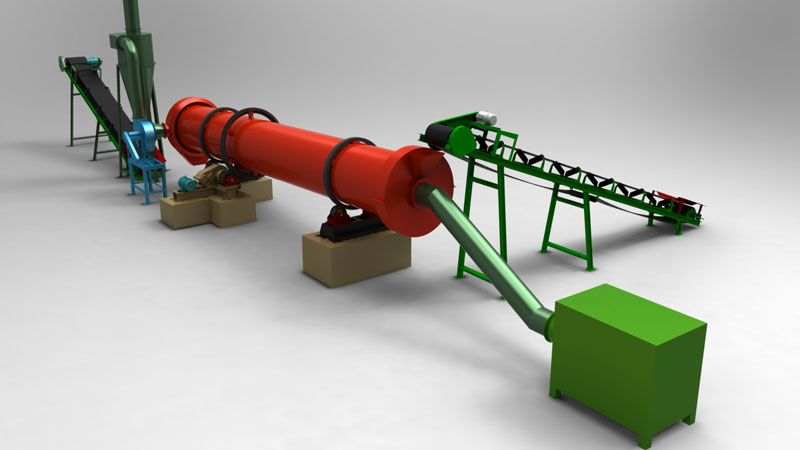

A complete pellet plant typically includes:

Each component is engineered to ensure:

India’s biomass pellet production capacity is expanding, yet the demand continues to increase — especially due to government policies encouraging biomass co-firing in power plants and reducing open-field stubble burning. Current production capabilities stand at thousands of tonnes per day, while demand far exceeds it, creating significant opportunities for investors and manufacturers in this sector.

With the National Bioenergy Mission and MNRE subsidy initiatives, biomass pellet plant investors can get attractive financial assistance, making it easier to launch or scale their operations.

A high-performance pellet plant usually includes:

✔ Raw biomass preprocessing units (cleaning, drying, grinding)

✔ Pellet mills and pellet presses

✔ Cooling and packaging systems

✔ Control and automation for efficient running

Ensuring top-quality equipment results in consistent pellet density, high calorific value, and low ash content — all crucial for better combustion and reduced emissions.

Switching to biomass pellets can bring major advantages:

With India’s strategic aim to expand clean energy and biomass utilization, partnering with experienced biomass pellet plant manufacturers like Pellet Burner India brings both economic and environmental benefits. Whether you are a first-time investor or an established energy player, our solutions deliver high performance, reliability, and sustainable growth.

Find Clear and Helpful Answers to the Most Common Questions

The cost depends on capacity, automation level, and raw material type. Small plants start from a few lakhs, while large industrial plants require higher investment.

Sawdust, paddy straw, wood waste, and agro residues are most commonly used due to availability and good calorific value.

Yes. Due to high demand, government support, and low raw material cost, biomass pellet manufacturing offers attractive returns.

Yes, Pellet Burner India provides complete installation, commissioning, and operator training.

In many applications, pellets can fully or partially replace coal, significantly reducing fuel costs and emissions.

Haryana

Yamuna Nagar-135001.

Karnataka

Bengaluru (Bangalore)-561203

Gujarat

Survey No 477, Tapar Ajapar Road Ajapar Kutch

Uttar Pradesh

Laharpur, Nabi Nagar Sitapur-261135

West Bengal

Bara Haripur Bangshihari Dakshin Dinapur-733121

Assam

Village – Dhansirikash,

P.O. – Shyamtila, P.S.-Dhula, Darrang,

Assam-78414

Plot number 22 khasra number 143 ground floor gali number 2 Kanjhawala industrial area delhi 110081

fireindustrialequipment@gmail.com

+91-9871484662

WhatsApp us